Flash steam

The flash steam

What is flash steam?

The more the pressure increases, the higher the boiling temperature of the water.

Conversely, if the pressure drops, the boiling temperature of water decreases.

The condensate discharged by the boiler and the trap retains the properties of the water as it was in the boiler.

Depending on the pressure maintained in the boiler, the condensate can reach very high temperatures.

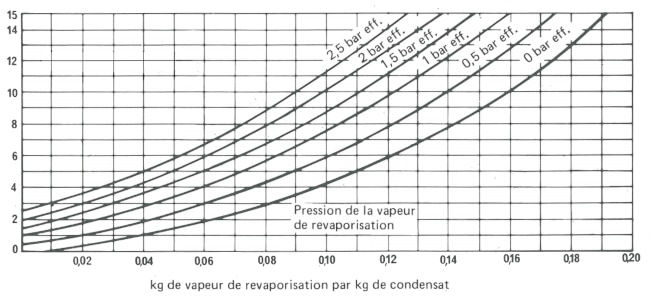

In the case where the condensate at 187.96 ° C for example, is discharged in an environment where it cannot maintain its liquid state at a temperature above 100 ° C, its excess heat causes overheating and then turns into latent heat by partial vaporization.

What is then called revalorization steam.

The condensate and the flash steam then feed a flash ball or vessel which separates the steam from the condensate.

The condensate in the liquid state is purged in the lower part of the vessel while the vapor is conveyed through the top of the vessel.

The flash steam then heats the feed water to the food tank via an exchanger.

The recovery of this flash vapor on certain processes generates significant energy gains and therefore, financial gains in the long term.